Page 38 - tmp

P. 38

Production of lactic acid from stillage in production of bioethanol

Olga Pantić

Regional center for talented youth Belgrade II, opantic@rocketmail.com

higher than the yield obtained with the triticale stillage.(2,3)

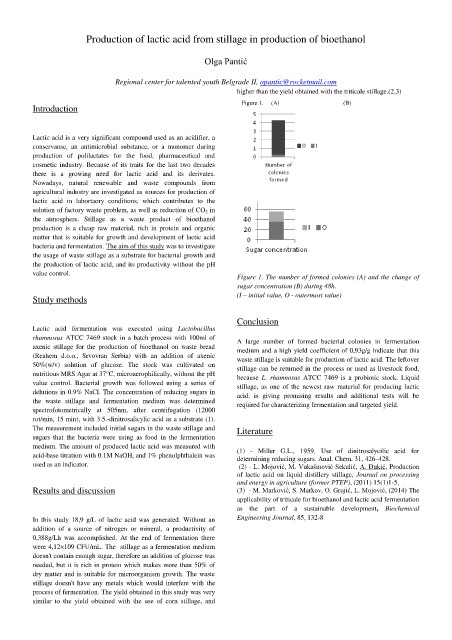

Figure 1. (A) (B)

Introduction

Lactic acid is a very significant compound used as an acidifier, a

conservanse, an antimicrobial substance, or a monomer during

production of polilactates for the food, pharmaceutical and

cosmetic industry. Because of its traits for the last two decades

there is a growing need for lactic acid and its derivates.

Nowadays, natural renewable and waste compounds from

agricultural industry are investigated as sources for production of

lactic acid in labortaory conditions, which contributes to the

solution of factory waste problem, as well as reduction of CO 2 in

the atmosphere. Stillage as a waste product of bioethanol

production is a cheap raw material, rich in protein and organic

matter that is suitable for growth and development of lactic acid

bacteria and fermentation. The aim of this study was to investigate

the usage of waste stillage as a substrate for bacterial growth and

the production of lactic acid, and its productivity without the pH

value control.

Figure 1. The number of formed colonies (A) and the change of

sugar concentration (B) during 48h.

Study methods (I – initial value, O - outermost value)

Conclusion

Lactic acid fermentation was executed using Lactobacillus

rhamnosus ATCC 7469 stock in a batch process with 100ml of A large number of formed bacterial colonies in fermentation

axenic stillage for the production of bioethanol on waste bread medium and a high yield coefficient of 0,93g/g indicate that this

(Reahem d.o.o., Srvovran Serbia) with an addition of axenic waste stillage is suitable for production of lactic acid. The leftover

50%(w/v) solution of glucose. The stock was cultivated on stillage can be returned in the process or used as livestock food,

nutritious MRS Agar at 37°C, microaerophilically, without the pH because L. rhamnosus ATCC 7469 is a probiotic stock. Liquid

value control. Bacterial growth was followed using a series of stillage, as one of the newest raw material for producing lactic

delutions in 0.9% NaCl. The concentration of reducing sugars in acid, is giving promising results and additional tests will be

the waste stillage and fermentation medium was determined required for characterizing fermentation and targeted yield.

spectrofotometrically at 505nm, after centrifugation (12000

rot/min, 15 min), with 3.5.-dinitrosalicylic acid as a substrate (1).

The measurement included initial sugars in the waste stillage and Literature

sugars that the bacteria were using as food in the fermentation

medium. The amount of produced lactic acid was measured with (1) - Miller G.L., 1959. Use of dinitrosalycilic acid for

acid-base titration with 0.1M NaOH, and 1% phenolphthalein was determining reducing sugars. Anal. Chem. 31, 426–428.

used as an indicator. (2) - L. Mojović, M. Vukašinović Sekulić, A. Đukić, Production

of lactic acid on liquid distillery stillage, Journal on processing

and energy in agriculture (former PTEP), (2011) 15(1)1-5.

Results and discussion (3) - M. Marković, S. Markov, O. Grujić, L. Mojović, (2014) The

applicability of triticale for bioethanol and lactic acid fermentation

as the part of a sustainable development, Biochemical

In this study 18,9 g/L of lactic acid was generated. Without an Engineering Journal, 85, 132-8

addition of a source of nitrogen or mineral, a productivity of

0,388g/Lh was accomplished. At the end of fermentation there

were 4,12×109 CFU/mL. The stillage as a fermentation medium

doesn't contain enough sugar, therefore an addition of glucose was

needed, but it is rich in protein which makes more than 50% of

dry matter and is suitable for microorganism growth. The waste

stillage doesn't have any metals which would interfere with the

process of fermentation. The yield obtained in this study was very

similar to the yield obtained with the use of corn stillage, and